Forced External Circulation Vacuum Evaporator (for paste, syrup, jam and other high viscous liquid product)

It is our latest generation product which is made through continuous improvement and upgrading based on our rich experience and the new technologies from Italy. It is specially used for fruit paste/jam (tomato paste, mango puree, peach/apricot paste, strawberry jam, chilli paste, etc.), fruit pulp, syrup, food gum and other high viscous product’s continuous low temperature concentration under vacuum. There are single effect, double-effect, tri-effect, multi-effect structures as per the processing capacity. The processing capacity we can do is from 300L to 35000L per hour water removal.

1) Tri-effect structure

2) Double-effect structure

3)Single-effect structure

|

Item |

Specification |

|

Application |

Specially used for fruit paste/jam (tomato paste, mango puree, peach/apricot paste, strawberry jam, chilli paste, etc.), fruit pulp, syrup, food gum and other high viscous product’s continuous low temperature concentration under vacuum. Can concentrate tomato paste from 4.5~5.5% to 28~30%, 30~32% or 36~38%Brix product as per clients’ requirements. |

|

Process capacity |

300~35000L per hour water removal |

|

Main characters |

1- Incorporated Italian technologies and made as per Euro standard. 2- It is made through continuous improvement and upgrading based on our rich experience. 3- Forced external circulation with counter-flow type structure which is specially used for fruit & vegetable paste, jam, fruit pulp, syrup and other high viscous product’s vacuum evaporation and can retain the natural color, flavor and nutrients of the product at the maximum. 4- Be composed of tubular heater, vacuum evaporation chamber, multi-stage condenser, pumps (product circulation pump, product input & outlet pump, vacuum pump, water pump), auto PLC control system, valves, meters & gauges, operation platform, and etc. 5- Main structure with high quality food class stainless steel. 6- Continuous product’s automatic input and output and the final product’s Brix consistency are fully control by PLC system. 7- The condenser can be recycled into the steam boiler. 8- Compacted structure, stable running, high efficiency and energy-saved performance. |

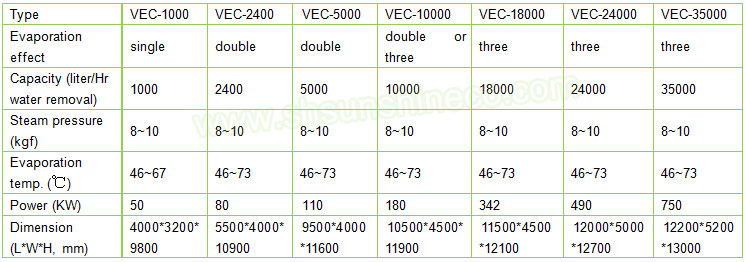

Technical Parameters: