Basic Description:

|

ITEM

|

SPECIFICATION

|

|

Processing raw material

|

Fresh tomato, apple/pear, tropical fruits(mango/pineapple/guava/banana/papaya), citrus fruits, etc.

|

|

Final product

|

1- Fruit juice/paste concentrate

2- NFC fruit juice (100% fresh)

|

|

Final product package

|

1- Aseptic bag (3L/5L/20L/220L)

2- Small package (pouch, glass bottle, plastic bottle, tin can, etc.)

|

|

Process capacity

|

50~300kg/hour fresh fruits input

|

|

Budget

|

about 100,000~200,000USD

|

|

Main characters

|

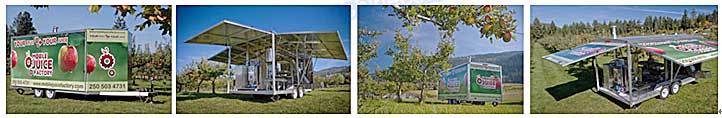

1- Mobile juice factory, small place required. It can be transported directly to the farmland with the mounted vehicle with a generator to process the freshest fruits, which can eliminate the transporting cost and the damage on the fruit’s quality during the long-distance transportation from the farmland to the fixed processing plant as traditional.

2- The freshest fruits can be processed in the farmland, which can retain the fresh fruits’ color, flavor and nutrients in the final product for premium high market.

3- The investment is small compared to having a brick and mortar business, no need additional civil construction and water, electricity, steam’s auxiliary facilities.

4- With the right operation, you can pay off your investment in as little as one year. It is particularly suitable for small entrepreneur or orchardist.

5- It will be custom-made using the latest Italian technology, the highest quality stainless steel (food class SUS304/SUS316) and the finest craftsmanship to European standard.

6- Continuous processing, high automatic, simple operation, stable running with high efficiency, compacted structure, energy-saved and environment-friendly.

|

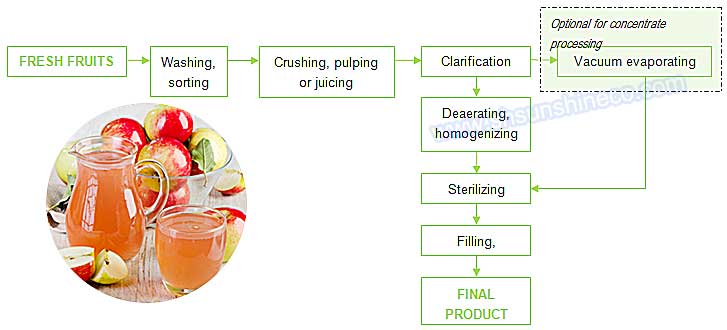

Process Flow (typical)

Why Buy A Juice Factory?

Why Buy A Juice Factory?