Citrus juicer (glass-pressing machine)

General Description

|

Item |

Detailed description |

|

Function |

Used for peeling, seeding, pitting, beating and refining of tomatoes, strawberries, blueberries, raspberries, mulberries, bananas, hawthorn, apricot, pumpkin and other fruit and vegetable material. |

|

Process capacity |

2.5~3 ton/Hr per machine |

|

Main features |

1. Cooperating with Italian supplier, imitating Italy FMC special cup type juice machine structure, citrus fruit juicer is well developed. 2. It consists of the frame, power system, mechanical transmission system, juicing system, essential oils spray device, gas and safety control system components; juice system is the core part of the juicer, including the upper and lower pressing cup, upper and lower cutter, filter tube, perforated pipe, juice collecting device. 3. Cup Press has high juice yield (up to 40%~45%), low initial juice taste, good taste and high quality. 4. Graded according to the different diameters of citrus fruit, and then select a different cup of juice juicer to juice. 5. In the process, juice, peel, core residues and essential oils were separated through four different channels. 6. Automatic cleaning interface, built-in multi angle spray head, high degree of automation 7. Automatic shutdown if fault, air pressure monitoring as well as sound and light alarm improve the safety degree. 8. Streamlined appearance, compact structure, small floor space, saving space. 9. The part contacting with the material is made of high-quality stainless steel. 10. With a reasonable structure, high degree of automation, squeezing out the juice is high, production stability, simple operation, low operating cost, low failure rate and so on. |

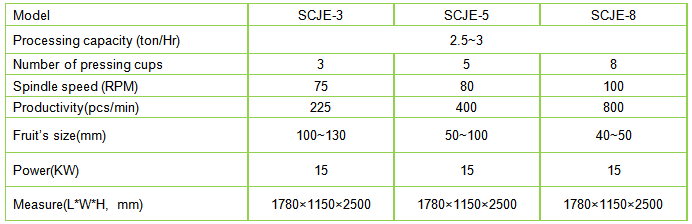

Technical Parameters