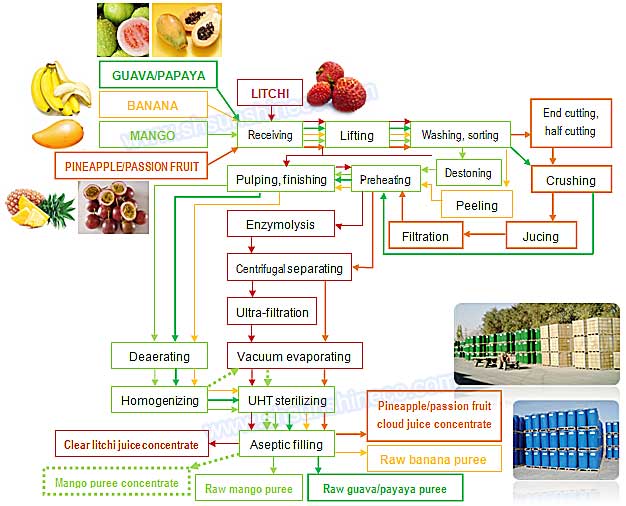

Process Flow (typical):

|

ITEM

|

SPECIFICATION

|

|

Major material

|

fresh tropical fruits (mango/pineapple/banana/guava/papaya/passion fruit/litchi)

|

|

Minor ingredient

|

Vc, citric acid (adding during juice extraction)

|

|

Final product

|

juice/puree/paste/concentrate

|

|

Final product package

|

aseptic bag (5L-220L, 1000L)

|

|

Process capacity

|

2~25tons/hr fresh fruits input

|

|

Budget

|

200,000~2,500,000USD

|

|

Main characters

|

1- Different juice extraction machine designed particularly upon different fruits so as to extract the juice efficiently at the maximum.

2- The nature flavor, color and nutrients can be retained at the maximum by means of multi-effect low temp falling film vacuum evaporation and UHT short time sterilization.

3- The UHT sterilizer and aseptic bag filler is incorporated Italian technologies and improved based on our rich experience, which can retain the fruits’ nature color, flavor and nutrition at the maximum. As well, our patented technology (the heat regeneration by the cold and hot product’s exchange) for sterilizer can save the energy over 30% than traditional.

4- The design of the process flow and the piping consider to retain the original natural flavor, aroma, color and nutrient at the maximum. For example, all the temp rising or dropping are finished in a very short time and short distance to avoid the flavor’s escaping or disruption during the heat treatment.

5- The optimal proposal is designed and customized upon the client’s project specified requirements and actual conditions based on the principle of “advanced process flow, simple structure equipment, reliable running and energy saved”. Meanwhile, we can design multi-fruit combined processing line as per the local resource available so as to maximum the equipment’s using efficiency.

6- The PLC control system and main electric components from SIEMENS, SCHNEIDER or other reliable international brand to ensure the reliable and high auto running.

|

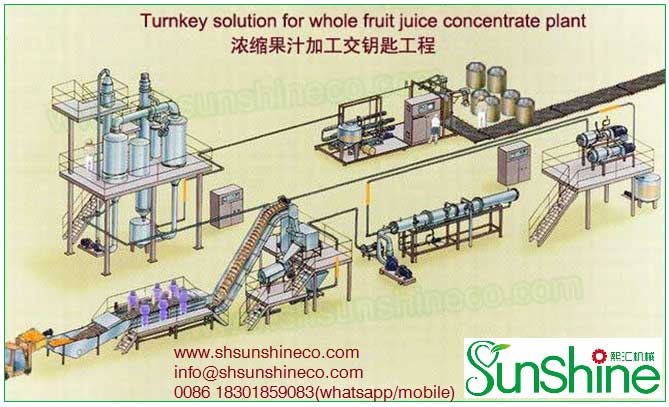

Photos (for reference):